Needle roller bearings, according to the direction of bearings load, can be divided into radial bearings and thrust bearings. Among them, radial bearings include various series of stamping outer ring type, solid type and special purpose bolt type and ring type roller needle roller bearings

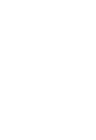

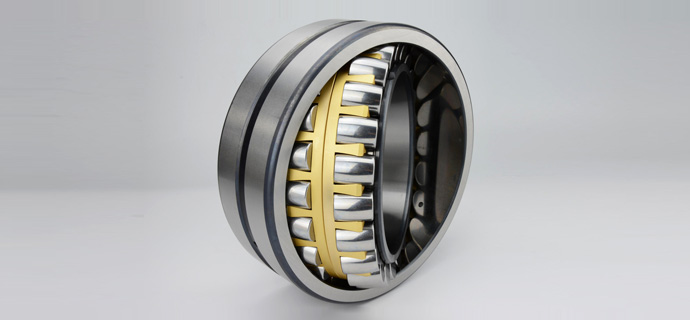

Among them thrust spherical roller bearings, the middle of the roller bulge, has the function of heart adjustment Therefore, the bearings is not affected by installation errors and shaft deflection Standard retainer for machined brass; The E - type product adopts the stamping processing retainer, has the characteristic of large load capacity

The standard design of EA type is oil hole and oil groove. For other types, oil hole and oil groove can also be provided to supply lubricant。In addition, use bearings with oil groove, oil hole, because the bearings oil groove depth is limited .Therefore, it is more effective if oil groove is also provided on the inner diameter of the shell

Tapered roller bearings can bear radial loads, as well as axial loads in one direction. When the load is applied to the bearings, the axial component force will be generated. Therefore, as with angular contact ball bearings, two bearings are generally used in parallel, or the form of double-row bearings must be used. In this case, an appropriate internal clearance can be set according to the adjustment of the spacing between the inner and outer rings, because the inner and outer rings can be disassembled separately. According to the different size of contact Angle, they are divided into ordinary cone Angle, cone Angle, large cone Angle bearings. According to the number of roller columns they can be divided into two rows and four rows of tapered roller bearings, In general, the use of steel plate stamping cage, large size tapered roller bearings also use pin shaft cage

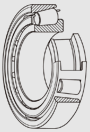

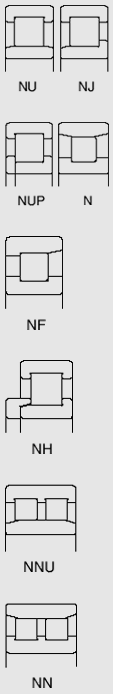

NU,NJ,NUP,N and NF single-row bearings, and NNU and NN double-row bearings are divided according to whether or not the collar is flanged .The bearings inner ring, outer ring detachable structure .Cylindrical roller bearings with inner ring or outer ring without guard, the inner ring and outer ring can be moved relatively as axial direction, so it can be used as free end bearings A cylindrical roller bearings with two guard edges on one side of the inner ring or outer ring and a single guard edge on the other side of the ring can bear a certain degree of axial load in one direction. Double row cylindrical roller bearings, high rigidity to radial load is mainly used for machine spindle, generally used steel plate stamping cage, or copper alloy car cage. But some used polyamide forming cage According to the cylindrical roller edge of the presence or absence, he is divided into the following situations